Those who want to coat have to cool down!

Many flexible substrates such as paper and foil can have a coating on one or both sides to modify and/or make the substrate suitable for eventual application purposes.

Primer coatings, top coats, flame retardant products or anti-slip coatings are all examples, as well as siliconisation or the application of wax emulsion.

The use of film stretching units, using chamber doctor blades and anilox rollers from a well-known German manufacturer, is a technologically modern and pioneering type of coating. With these, both sides of the web can be coated with the same or different materials in one process. These film stretching units work with cylindrical or linier anilox rollers moving together or in opposite directions to the transfer rollers. Their closed, permanently pressurised chamber doctor blade applies to the coating material on the anilox roller surface, whereby the adjustable chamber pressure determines the trapping of the screen and so allows a variation of applied quantities in the application of the same anilox roller. Generally, the film stretching technology is very flexible and offers the user many possibilities.

Film stretching units are mostly found inline in paper and foil manufacturing plants (e.g. stretch or cast film plants) or offline in coating machines, where web widths up to 330 cm and production speeds of up to 750 m/min are currently possible.

With the above mentioned blade application technology, it must be considered that the coating and web would heat up during the process if the rollers were not cooled down. Without a cooling system, the coating would coagulate / stick together and a poor quality surface would be produced.

However, when we talk about cooling here, it is not as simple as being able to put "cold water" through the rollers – quite the contrary: the cooling media must pass through the rollers at the correct temperature and in the correct quantity to extract a precisely measured amount of heat from the web and coating.

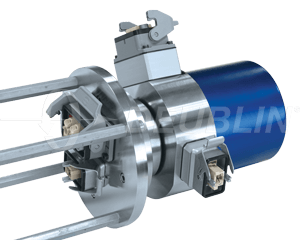

In order to put this specific application into practice, the machine manufacturer is using DEUBLIN Rotating Unions: They provide interfaces between rotating rollers in the film stretching unit and the supply lines of the tempered cooling media. The quality of the rotating unions, which are used, therefore has an influence on the process.

The flow-optimised construction in high-precision finish reduces the turbulence of the agent to a minimum; at the same time the flow capacities are very predictable, as no unexpected cross-sectional reductions arise. So the defined energy extraction can take place across the entire width of the roller, without cultivating "hot spots" or areas, which are too cold.

In this primary position, the relatively small component "Rotating Union" has a great influence on the quality of the goods produced.

As it is also known, the rotating unions are parts which are subject to wear; there is however a serious difference in the durability! High quality rotating unions reduce the relative frequency of maintenance services and would (when fitted correctly) help to reduce unplanned machine breakdowns as "the most expensive machine condition".

And as the machine manufacturer has film stretching units in operation globally, it has been fundamental for them to have a partner for maintenance, servicing and care of the rotating unions, who is located close to customers all over the world.

The manufacturer is confident that the overall quality of his systems, the quality of the components and the after-sales services make a positive impact on his customers and that they will also see value for money, in terms of cost, for his customers in the truest sense of the word.

Drehdurchführungen mit elektrischem Schleifring

sind integrierte Baugruppen bestehend aus der Drehdurchführung und dem elektrischen Schleifring.

Durch langjährige Erfahrung des Herstellers DEUBLIN ist die Technologie unter Verwendung spezieller Materialkonfigurationen auf langlebigen Betrieb sowie eine zuverlässige Verbindung von Signalen und Leistung ausgelegt.

Ihr Einsatzgebiet umfasst neben der bekannten Anwendung in Onshore- und Offshore-Windenergieanlagen ebenso die Verwendung in der Halbleiter-Industrie, bei der Lebensmittelverarbeitung, in Werkzeugmaschinen, Kunststoffformmaschinen, Wickelmaschinen und vielem mehr.

DEUBLIN entwickelt und produziert die Schleifringe für die Anwendung kundenspezifisch im Hinblick auf Betriebs- und Lagerungstemperatur, Beschleunigung, mechanische Vibration. Auf einfache Montage wird ebenso Wert gelegt wie auf lange Standzeit und Reduktion der Wartungszeiten, da die elektrischen und hydraulischen Anschlüsse des Rotors als Teil des Installations- oder Abbauprozesses ein- oder ausgesteckt werden und diese Kabel- und  Schlauchverbindungen nicht separat getrennt werden müssen.

Schlauchverbindungen nicht separat getrennt werden müssen.

Auch die Drehdurchführung mit elektrischem Schleifring gibt es als kundenspezifische Variante mit Einkanal bis hin zu vielen Kanälen. Nach Kundenvorgabe werden die elektrischen Anschlüsse und die Schutzart konfiguriert. Das Bürstenmaterial für die Eindraht- und Mehrdrahtbürsten sowie die Technik der Schleifringe werden anhand der Anforderungen bei Signal- oder Leistungsübertragung gewählt.

Sie möchten konkret anfragen? Benutzen Sie einfach unser Kontaktformular!

Sie möchten sich genauer informieren? Gehen Sie zu unserer Startseite!